This is the right oil for your lathe!

Maintenance of a lathe or machine in general, is very important for the lifespan of your machine. Replacing or applying oil on time is something you should take into account as a matter of course! Choosing the right oil is also very important. Here is a brief overview of the oils you can use.

Basically, the lathe only has three parts where you apply lubricants:

With the oils for the gears, we are talking about the oil for in the norton case, fixed head and lock case. This contains various gears, which need to be kept well lubricated. The gears in the norton case take care of the feeders and threading, while the lock case controls the feeders and threading.

To maintain the gears in these gearboxes, our mechanics always use hydraulic 46 oil

\

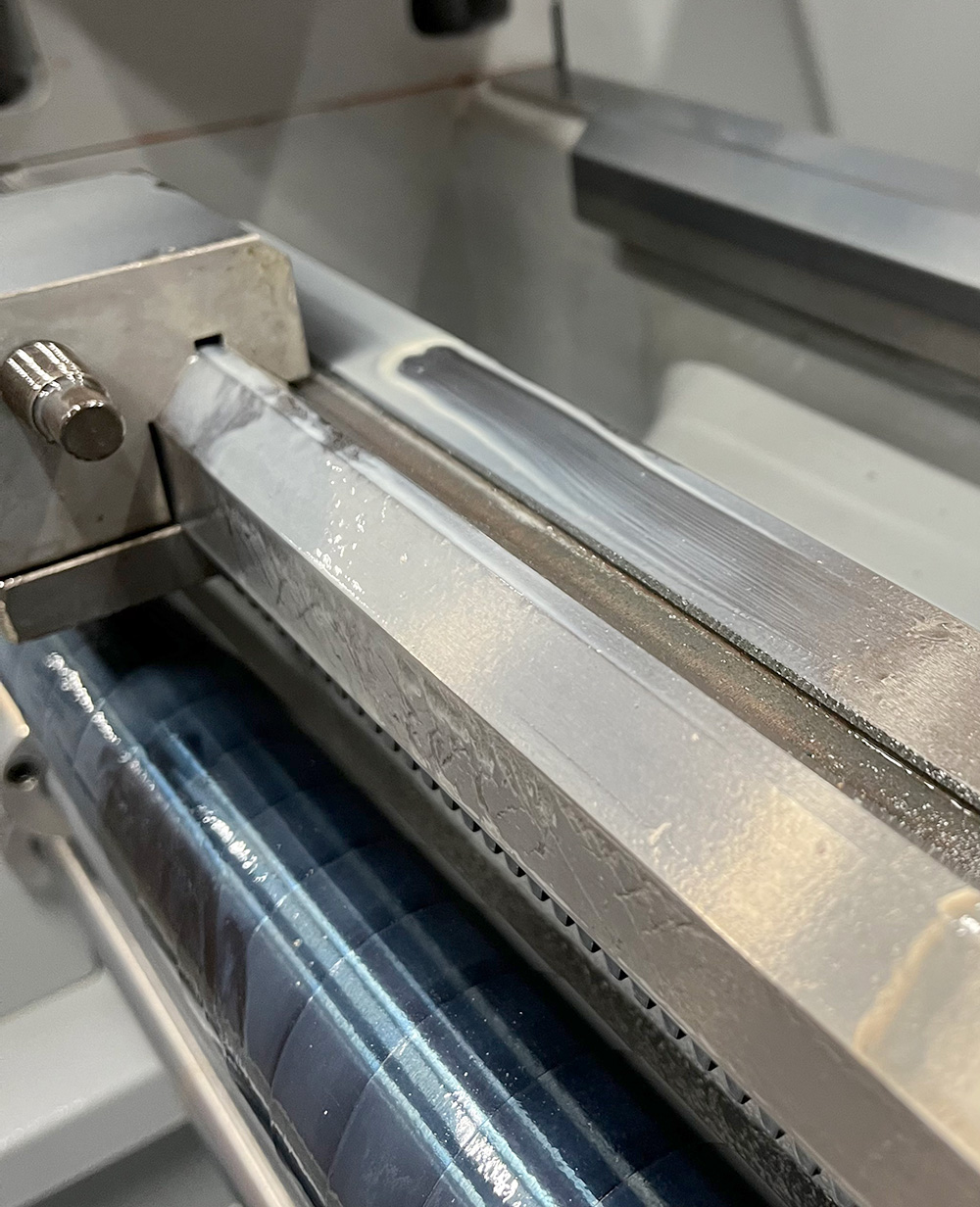

The bedways ensure smooth guidance of the support towards the fixed head and back, as well as guiding the loose head forwards and backwards. To ensure this runs smoothly and to avoid metal on metal as much as possible, it is wise to periodically lubricate the bedways with oil. This extends the life of the bedways on your lathe (or milling machine).

Often, so-called slideway or spindle oil is used for this, this would be hydraulic 68.

However, our technicians like to use hydraulic 46 oil for this purpose. This is a bit thinner and this ensures that the oil is less likely to slip on the slide ways.

This is a tip we would like to give you!

For a smoother result from your turning (or other machining work), it is very important to cool your equipment properly. Not only does your lathe appreciate this, the tool and the material you will be machining will appear to be smoother. Another plus is that it will not smoke and squeak. So this is better for your health and your hearing, which makes it a nice bonus. There are many choices in cooling oils. This also depends on the material you are going to process. We have 3 standard types, which will definitely help you in 9/10 cases:

JT-14: standard emulsifiable cutting oil for almost all applications. You can mix it 1:20, i.e. 1L of oil with 20L of water.

SOG 120 BLUE: this oil is suitable for non-ferrous metals, aluminium, magnesium and their alloys. Suitable for both turning and other machining applications.

SOG 20 EP BIO: this oil is suitable for all types of steel, to be used pure as well as in emulsion! The advantage of this oil is that it is biologically soluble. So it is better for the environment and saves a lot of dirt on your machine.